What Type of Ink Is Used in Pad Printing?

After more than ten years working as a pad printing and screen printing machine engineer, I can confidently say one thing:

Most pad printing problems are not caused by machines — they are caused by wrong ink decisions.

When buyers ask, “What type of ink is used in pad printing?”, they often expect a simple answer:

Solvent-based ink

One-component or two-component ink

But in real production, ink selection is never that simple.

Ink in pad printing is a system decision, tightly linked to:

Substrate material

Product geometry

Production volume

Environmental conditions

Machine configuration

Operator skill level

More importantly, ink choice directly affects equipment customization and procurement strategy.

This is something only people who have spent years inside factories truly understand.

This article explains pad printing inks from a real engineer’s perspective, not from brochures.

Table of Contents

Why Ink Plays a Bigger Role in Pad Printing Than in Other Printing Methods

Pad printing is unique because it relies on three material interfaces:

Ink ↔ steel cliché

Ink ↔ silicone pad

Ink ↔ product surface

If any one of these interfaces fails, printing fails — even if the machine itself is perfect.

That is why experienced engineers never talk about ink alone.

We always talk about “ink + pad + plate + machine + environment” as one system.

The Core Ink Types Used in Pad Printing

From real production lines, pad printing inks generally fall into four practical categories.

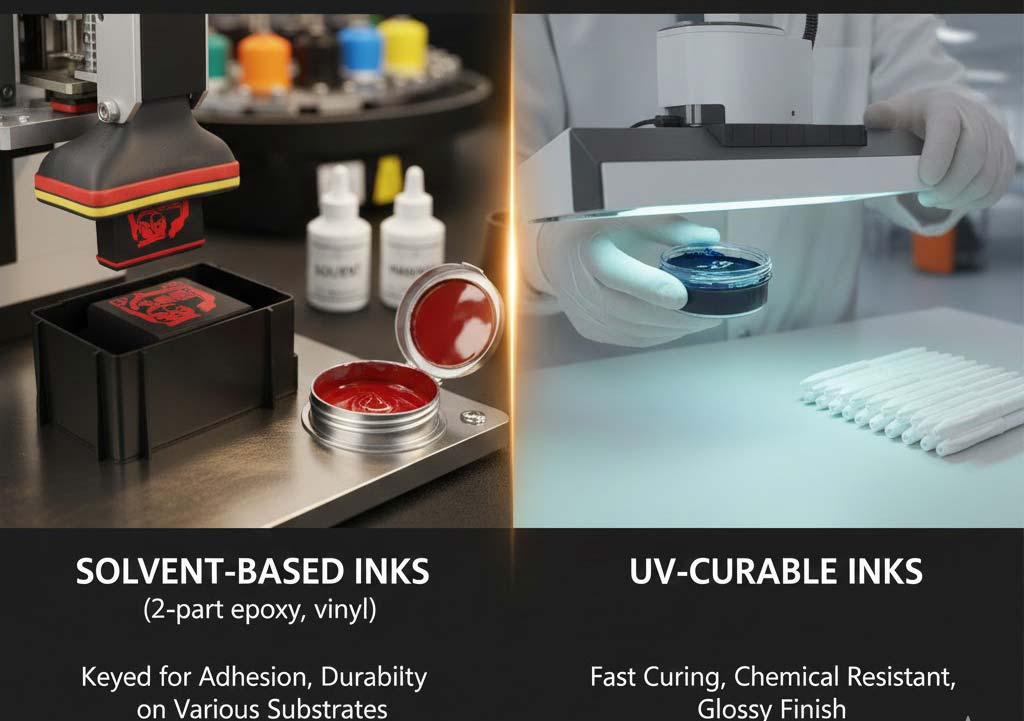

1. Solvent-Based Pad Printing Inks (The Industry Backbone)

Why Solvent-Based Inks Dominate Pad Printing

More than 80% of industrial pad printing applications still use solvent-based inks.

The reason is simple:

They transfer cleanly

They release well from silicone pads

They bond reliably with plastics and metals

From an engineering standpoint, solvent-based inks offer the widest tolerance window.

They forgive:

Minor humidity changes

Small temperature fluctuations

Operator inconsistencies

This forgiveness is critical in mass production.

Typical Applications

ABS, PC, PVC, PS plastic parts

Painted or coated metal surfaces

Consumer electronics housings

Automotive interior components

If your product uses injection-molded plastics, solvent-based ink is almost always the starting point.

One-Component vs Two-Component Inks

One-Component (1K) Inks

Air-drying

Easier to use

Shorter setup time

Best for:

Short production runs

Promotional products

Non-critical adhesion requirements

Two-Component (2K) Inks

Mixed with hardener

Chemical curing

Much stronger adhesion

Best for:

Automotive parts

Medical devices

Products requiring abrasion or chemical resistance

Procurement reality:

Factories that underestimate ink curing requirements often blame the machine later.

2. UV-Curable Pad Printing Inks (Growing but Not Universal)

UV pad printing inks exist, but they are far less forgiving than many buyers expect.

Advantages

Instant curing

Cleaner production environment

No solvent evaporation

Engineering Challenges

Requires precise UV energy control

Sensitive to surface energy

Pad contamination issues are common

From my experience, UV inks only work well when:

Product geometry is simple

UV exposure is uniform

Operators are well trained

This is why UV pad printing systems must be custom-engineered, not bought off the shelf.

3. Silicone and Special-Surface Inks

Printing on silicone, rubber, or low-surface-energy materials is a different game entirely.

Key Challenges

Ink rejection

Poor wetting

Long-term adhesion failure

These inks often require:

Plasma or flame pretreatment

Special pad materials

Controlled ink viscosity

Important procurement note:

If a supplier claims “our standard machine prints silicone easily,” that is a red flag.

4. Food-Grade and Medical-Grade Inks

In regulated industries, ink selection is not just technical — it is legal.

Requirements Often Include

Low migration

Biocompatibility

Sterilization resistance

Traceability documentation

From an engineer’s perspective, these inks:

Narrow the process window

Increase validation workload

Require more stable machine platforms

This directly affects machine price and customization level.

Ink Properties That Matter More Than Ink Type

Experienced engineers never ask only “What ink?”

We ask “What properties?”

1. Viscosity Stability

Ink viscosity changes with:

Temperature

Solvent evaporation

Cycle speed

Machines designed for long-run production often need:

Ink cup systems

Temperature-controlled ink trays

Automated solvent dosing

This is why high-end pad printing machines cost more — not because of steel, but because of process control.

2. Drying Speed vs Transfer Efficiency

Ink that dries too fast:

Sticks to the cliché

Does not release from the pad

Ink that dries too slowly:

Smears on the product

Extends cycle time

Balancing this is an engineering problem, not a purchasing checkbox.

3. Adhesion vs Elastic Recovery

Strong adhesion often conflicts with good pad release.

This is where:

Pad hardness selection

Pad shape design

Ink formulation

must work together.

How Ink Choice Directly Impacts Machine Customization

1. Ink System Design

Different inks require different systems:

Open ink wells

Sealed ink cups

Agitation mechanisms

A buyer choosing ink first after buying the machine often ends up retrofitting later — at higher cost.

2. Pad Selection and Pad Geometry

Ink chemistry determines:

Pad hardness (Shore A)

Pad surface energy

Pad lifespan

A standard pad rarely works for:

High-viscosity inks

UV inks

Silicone inks

This is why custom pad development is part of serious machine procurement.

3. Environmental Control Requirements

Some inks demand:

Constant temperature

Controlled humidity

Cleanroom-level dust control

If these needs are ignored during procurement, production instability is guaranteed.

Real Procurement Habits I See After 10+ Years

What Experienced Buyers Ask First

“Have you tested this ink on our material?”

“What is the yield rate after 8 hours?”

“What fails first: pad, ink, or cliché?”

These are engineering questions, not sales questions.

What Inexperienced Buyers Ask First

“How many colors can it print?”

“Is this machine cheaper?”

These buyers often return six months later with problems.

Common Procurement Mistakes Related to Ink

Mistake 1: Assuming Ink Is Universal

No ink works on all materials.

If a supplier claims that, walk away.

Mistake 2: Ignoring Long-Term Ink Cost

Ink price per kilogram means nothing.

What matters is:

Ink consumption per 1,000 prints

Scrap rate

Rework cost

Mistake 3: Buying Machines Without Ink Testing

Any serious manufacturer should:

Test your ink

Test your material

Simulate your production cycle

Without this, the machine price is meaningless.

How Professional Manufacturers Approach Ink + Machine as a System

From the manufacturing side, responsible suppliers do the following:

Ask about ink before quoting

Design pad and fixture around ink behavior

Adjust machine timing based on ink drying curve

Provide ink parameter documentation

This is the difference between a machine seller and a solution provider.