Is Pad Printing the Same as Screen Printing?

In industrial manufacturing, printing is not just about putting ink on a surface. It directly affects product appearance, brand consistency, production efficiency, defect rates, and long-term operational costs.

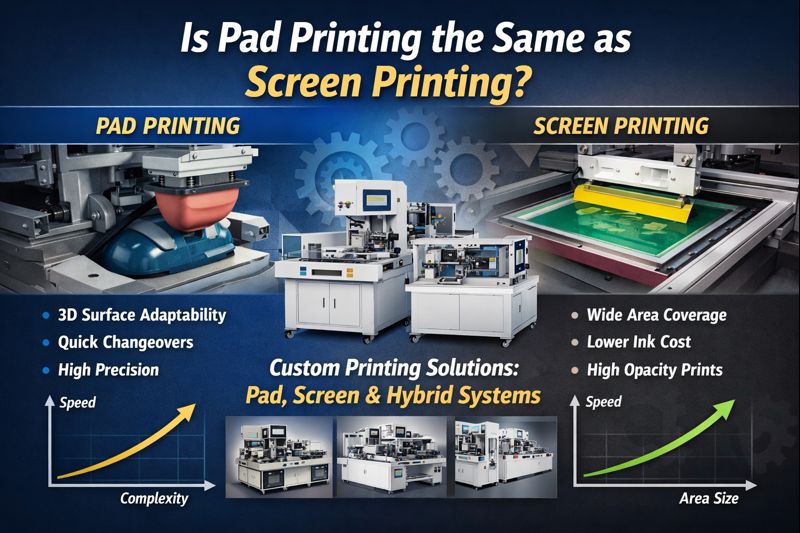

Among the most commonly compared technologies are pad printing and screen printing. Buyers often ask a seemingly simple question:

Is pad printing the same as screen printing?

From an engineering and procurement perspective, the answer is no—and the differences matter far more than most buyers initially expect.

This article analyzes pad printing and screen printing from a procurement decision-making viewpoint, supported by process data, cost structures, application scenarios, and equipment engineering considerations. It also explains why working with a manufacturer that has in-house machine design and development capability offers a decisive advantage for long-term production success.

Table of Contents

1. Why Procurement Teams Struggle with Pad vs. Screen Printing Decisions

In many factories, the choice between pad printing and screen printing is not made by engineers alone. It involves:

Purchasing managers balancing budget and ROI

Production managers focused on throughput and yield

Quality teams concerned with consistency and defect rates

R&D teams planning future product variations

The challenge is that pad printing and screen printing overlap in application but differ fundamentally in capability.

From a procurement standpoint, the wrong choice often leads to:

Over-investment in equipment capacity

Bottlenecks caused by unsuitable processes

High scrap rates on complex parts

Frequent tooling changes and downtime

Understanding the engineering-level differences is essential before committing capital.

2. Core Process Differences: Pad Printing vs. Screen Printing

2.1 Printing Principle Comparison

| Aspect | Pad Printing | Screen Printing |

|---|---|---|

| Ink transfer | Silicone pad transfers ink | Squeegee pushes ink through mesh |

| Contact surface | Flexible, compressible pad | Flat or mildly curved substrate |

| Plate / screen | Steel or polymer cliché | Polyester or stainless mesh |

| Ink thickness | Thin, controlled | Thicker ink layer |

| Setup complexity | Moderate | Relatively simple |

Pad printing excels in 3D geometry adaptation, while screen printing dominates flat, high-area coverage.

2.2 Surface Adaptability (Critical for Procurement Planning)

Procurement teams must consider not just current products, but future SKU evolution.

Surface compatibility comparison:

| Surface Type | Pad Printing | Screen Printing |

|---|---|---|

| Flat plastic panels | ✔️ | ✔️ |

| Cylindrical parts | ✔️ | ⚠️ Limited |

| Concave surfaces | ✔️ Excellent | ❌ |

| Convex surfaces | ✔️ Excellent | ❌ |

| Textured micro-surfaces | ✔️ | ⚠️ |

| Large flat areas | ⚠️ | ✔️ Excellent |

Key procurement insight:

If product geometry is likely to evolve, pad printing offers higher future-proofing.

3. Production Data Comparison: What the Numbers Tell Us

3.1 Typical Production Speed (Per Hour)

| Process | Manual | Semi-Automatic | Fully Automatic |

|---|---|---|---|

| Pad printing | 500–1,200 pcs | 1,800–3,000 pcs | 4,000+ pcs |

| Screen printing | 300–800 pcs | 1,200–2,000 pcs | 3,500+ pcs |

Screen printing often appears faster on paper, but only for flat, standardized products.

3.2 Setup & Changeover Time (Average)

| Factor | Pad Printing | Screen Printing |

|---|---|---|

| Plate/screen change | 10–20 min | 15–30 min |

| Color registration | Automated possible | Manual-intensive |

| Fixture change | Modular | Often product-specific |

For factories running multiple SKUs, pad printing systems with modular fixtures significantly reduce downtime.

4. Cost Structure Breakdown from a Buyer’s Perspective

4.1 Initial Equipment Investment

| Equipment Type | Typical Cost Range |

|---|---|

| Pad printing machine | Medium |

| Screen printing machine | Low to Medium |

| Automation integration | Medium to High (both) |

Procurement trap:

Lower upfront cost does not equal lower total cost of ownership (TCO).

4.2 Long-Term Operating Costs (5-Year View)

| Cost Element | Pad Printing | Screen Printing |

|---|---|---|

| Consumables | Medium | Low |

| Scrap rate | Low (complex parts) | High (complex parts) |

| Labor dependency | Low–Medium | Medium–High |

| Rework cost | Low | Medium |

For products with irregular geometry, pad printing consistently delivers lower scrap and rework costs.

5. Quality & Consistency: What Buyers Often Underestimate

5.1 Print Precision

Pad printing achieves:

Line width down to 0.1 mm

High repeatability on curved surfaces

Stable ink transfer under controlled pressure

Screen printing excels in:

Bold, opaque graphics

High ink thickness for durability

Large-format branding

Procurement conclusion:

Choose based on functional requirement, not appearance alone.

6. Application-Based Procurement Recommendations

6.1 Industries Where Pad Printing Is Preferred

Medical devices (catheters, syringes, housings)

Electronics (buttons, connectors, housings)

Automotive interior parts

Promotional items with complex shapes

6.2 Industries Where Screen Printing Dominates

Glass panels

Appliance control panels

Flat signage

Packaging boards

In many factories, the optimal solution is not either/or, but integrated use of both technologies.

7. Why Machine Manufacturing Capability Matters in Procurement

Many buyers focus only on machine price. Experienced procurement professionals evaluate machine makers, not just machines.

As a manufacturer with in-house pad printing and screen printing machine design and development capability, we observe several recurring procurement risks when buyers source from traders or assemblers.

7.1 Limitations of Non-Manufacturing Suppliers

Fixed machine structures

Limited fixture customization

No firmware-level optimization

Long response time for engineering changes

This results in:

Compromised print quality

Reduced production efficiency

Costly third-party modifications

8. Our Engineering Advantage: One-Stop Custom Printing Solutions

8.1 In-House Machine Development Capability

We design and manufacture:

Pad printing machines

Screen printing machines

Hybrid systems for complex workflows

This allows us to:

Modify stroke length, pressure, and cycle logic

Customize pad shapes and screen frames

Integrate vision systems and automation

8.2 One-Stop Customization from Procurement to Production

From a buyer’s standpoint, our value lies in reducing coordination cost:

| Stage | Buyer Pain Point | Our Solution |

|---|---|---|

| Requirement analysis | Unclear process match | Engineering feasibility study |

| Machine selection | Over/under specification | Data-driven configuration |

| Fixture design | Trial-and-error | CAD-based customization |

| Scaling production | Capacity bottleneck | Modular automation upgrade |

9. Data-Driven Equipment Selection: Our Typical Approach

When procurement teams engage us, we typically analyze:

Product drawings (2D/3D)

Annual volume forecasts

Defect tolerance requirements

Future SKU expansion plans

Based on this, we recommend:

Pad printing only

Screen printing only

Hybrid production lines

This engineering-led procurement approach prevents costly post-purchase modifications.

10. Final Answer: Is Pad Printing the Same as Screen Printing?

From an engineering and procurement perspective:

Pad printing and screen printing are not the same.

They solve different manufacturing problems.

Pad printing prioritizes surface adaptability and precision

Screen printing prioritizes area coverage and ink thickness

The real procurement question is not which process is “better,” but:

Which process delivers the lowest total cost, highest yield, and greatest flexibility over the equipment lifecycle?

11. Final Thoughts for Procurement Decision-Makers

For buyers sourcing printing equipment, the most important decision is not pad printing vs. screen printing, but:

Choosing a supplier with true machine manufacturing capability

Ensuring the system can be customized and upgraded

Reducing long-term operational risk

A printing machine is not just equipment—it is a production system.

Working with a manufacturer that can design, develop, customize, and support both pad printing and screen printing solutions under one roof gives procurement teams a decisive advantage in cost control, quality stability, and future scalability.